Compare

PLW 8616 [EL CT]

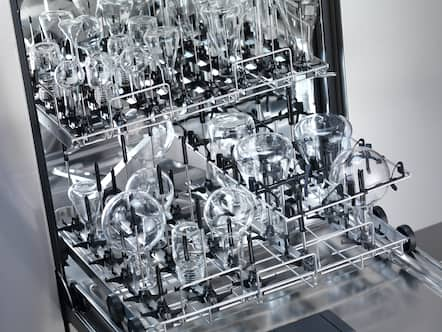

Laboratory glasswasher – double door with combi tank, 35 1/2" (900 mm) wide, 12.395 (351) ft³ (l) usable capacity.

- Performance/cycle, e.g., 216 laboratory bottles, 588 vials, or 294 pipettes

- Flexible use of the combi tank as a recycling/pre-heating tankCombi tank

Reduces cycle times and saves resources. - Flexible and simple – modular load carriers & SimpleLoad systemFlexible use of load carriers

The flexible load carriers from Miele Professional offer an extremely wide range of loading options. With a low number of load carriers combined with additional modules and inserts, the load carriers can be flexibly adapted to the wash items in just a few steps, optimizing both costs and the amount of space required.SimpleLoad

The SimpleLoad system makes reprocessing laboratory glassware considerably faster, simpler, and more efficient. The biggest advantage of the new system is that wash items can be positioned over nozzles both more simply and faster as it is no longer necessary to adjust the height of the holders thanks to the smart combination of nozzles and holding frames. This makes it easy to position items correctly. - Up to 60% less water consumption based on the load *e.g., 60% saving with 100 ml laboratory bottles in Universal Max program compared to Lab Universal program for PG 8527

- Efficient – high pump performance with the variable-speed pumpSustainable thanks to 2-pump technology

Smart 2-pump technology is at the heart of this laboratory glasswasher from Miele. The variable-speed pump is particularly flexible regarding the basket docking system. Using this pump, the wash pressure and water demand are adjusted in line with the relevant requirements – high pressure facilitates the removal of stubborn soiling, while low pressure guarantees complete soaking. This guarantees maximum cleaning performance while ensuring sustainable use of resources. - Reliable results – spray arm monitoring and conductivity meterSpray arm monitoring

Reliable cleaning performance thanks to the monitoring of the rotation speed of the spray arm.Conductivity monitoring

Reliably clean: Residue-free final rinse for perfect results.

Product benefits

Exclusive to Miele

SimpleLoad system** German patent DE 102 017 129 786 A1 and DE 102 017 129 799 A1

Simple loading with SimpleLoad

The new SimpleLoad system simplifies the loading of baskets and protects laboratory glassware during reprocessing.

Status indication via chamber lighting

Machine status displayed via chamber lighting

Convenient: the status of each program phase is indicated by the changing colors of the chamber lighting.

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

Integrated hot-air drying

Dried safely

All reprocessing items are dried efficiently using hot air filtered with a HEPA filter.

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

USB interface

Update quickly and securely

Easy access to Technical Service: Firmware updates can be performed via USB stick in order to save time.

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

Integrated printer

Logged on paper

For paper-supported documentation, the integrated printer produces a comprehensive report on the process.

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

Exclusive to Miele

SimpleLoad system** German patent DE 102 017 129 786 A1 and DE 102 017 129 799 A1

Simple loading with SimpleLoad

The new SimpleLoad system simplifies the loading of baskets and protects laboratory glassware during reprocessing.

Status indication via chamber lighting

Machine status displayed via chamber lighting

Convenient: the status of each program phase is indicated by the changing colors of the chamber lighting.

Clear text display

Text display

Everything at a glance: The display shows everything as clear text in the country-specific language.

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

Product details

PLW 8616 [EL CT]

EAN 4002516148166 / Article number 62861602USA / Material number 11179580

EAN 4002516148166 / Article number 62861602USA / Material number 11179580

| Model | Freestanding appliance, throughfeed, 2 glass lifting doors Vertical door opening The lift-door opens and closes the wash cabinet via a vertical, electronically controlled sliding movement. In this way, the work area in front of the labwasher remains freely accessible for transport trolleys, and loading and unloading conveyors. The lift-door in easy-to-clean full glass also allows for visual monitoring of the ongoing reprocessing. |

|---|---|

| Heating type | Electricity |

| Front/back | Stainless Steel |

| Side panels | Stainless steel |

| Single/multiple installations | |

| Loading via mobile units | |

| Electric door lock | |

| Buzzer, acoustic signal at end of program | |

| Easy-to-service construction |

| Narrow-neck glassware per cycle [number] | 216 |

|---|---|

| Test tubes per cycle [number] | 588 |

| Laboratory flasks per cycle [number] | 216 |

| Pipettes per cycle [number] | 294 |

| Circulation pump, Qmax in gal/min (l/min) | 105.68 (400) |

|---|---|

| Additional circulation pump for load carrier – direct coupling, Qmax in gal/min (l/min) | 600 |

| Variable-speed pump | Sustainable thanks to 2-pump technology Smart 2-pump technology is at the heart of this laboratory glasswasher from Miele. The variable-speed pump is particularly flexible regarding the basket docking system. Using this pump, the wash pressure and water demand are adjusted in line with the relevant requirements – high pressure facilitates the removal of stubborn soiling, while low pressure guarantees complete soaking. This guarantees maximum cleaning performance while ensuring sustainable use of resources. |

| Usable wash cabinet volume in L | 12.395 (351) |

| Tested operating hours Note Our machines undergo intensive testing under laboratory conditions. The actual operating hours may vary depending on actual usage behavior, maintenance, and care of the machine. | 15000 |

| Service life in wash cycles | 20000 |

| Electrical connection | 3 AC 208V 60HZ |

|---|---|

| Heater rating in kW | 18 |

| Total rated load in kW | 21 |

| Fuse rating in A | 60 |

| Cold water [number] | 2 |

|---|---|

| Hot water [number] Efficient hot water connection Connection to the warm water supply saves a lot of time and energy. | 1 |

| DI water [number] DI water supply Thanks to the connection for fully demineralized (DI water), these washer-disinfectors and thermal disinfectors facilitate optimum reprocessing results. Rinsing with fully demineralized water also protects valuable wash items from deposits and corrosion. | 2 |

| Required flow pressure in kPa | 200-1000 |

| Maximum water hardness (cold water/hot water) in gpg (mmol/l) | 4.153 (0.71) |

| Drain valve [DN] | 50 |

| Drain pump (optional) |

| Compressed air connection, technical [number] | 1 |

|---|---|

| Required air pressure, technical, in kPa | 600-800 |

| Drying unit heating type | Electricity |

|---|---|

| Air throughput in m³/h | 147.15 (250) |

| Temperature settings in 1° steps | 60-115 |

| Time settings in 1-minute steps | 1-240 |

| HEPA-filter class | H13 |

| HEPA-filter filtration efficiency (in accordance with DIN EN 1822) in % | 99.95 |

| HEPA-filter service life in h | 1000 |

| Electric heater rating in kW | 8 |

| External dimensions, net height in inches | 65 3/4 (1670) in (mm) |

|---|---|

| External dimensions, net width in inches | 35 7/16 (900) in (mm) |

| External dimensions, net depth in inches | 39 (990) in (mm) |

| External dimensions incl. toe-kick/drip pan and top casing, height in inches | 98 1/4 (2495) |

| External dimensions, gross height in inches Note Including packaging | 77 3/16 (1960) |

| External dimensions, gross width in inches Note Including packaging | 39 3/8 (1000) |

| External dimensions, gross depth in inches Note Including packaging | 44 1/2 (1130) |

| Wash cabinet, height in inches | 26 5/8 (675) |

| Wash cabinet, width in inches | 25 5/8 (650) |

| Wash cabinet, depth in inches | 31 1/2 (800) |

| In-feed height above floor in inches | 33 1/2 (850) |

| Net weight in lbs | 896 (406) |

| Gross weight in lbs Note Including packaging | 918 (416) |

| Maximum floor load in N/m² Maximum floor bearing capacity Maximum floor bearing capacity states the maximum weight (N) that can be placed on the supporting surface on which the appliance is installed. This maximum load bearing capacity is the result of adding up the weight of the machine, the load and the water in it, as well as the dynamic forces that occur during operation. | 8000 |

| Sound pressure LpA in cleaning and drying according to DIN EN ISO 11201 Emissions - sound pressure at workplace The emission sound pressure level provides a value for the noise emission created by the machine. Miele Professional machines have an extremely low sound pressure level. | <lt/>65 dB(A) re 20 µPa |

|---|

| Thermal disinfection | |

|---|---|

| Laboratory-glassware reprocessing | |

| Plastics | |

| Oil soiling | |

| Industrial parts cleaning |

| Ethernet interface | |

|---|---|

| External dispenser modules | |

| USB interface | |

| Central dispensing | |

| Peak-load negotiation / energy management |

| CE | |

|---|---|

| VDE (electrical safety) | |

| EN 61010-2-040 | |

| Machinery Directive 2006/42/EC |

Additional components and consumables

Find additional components and consumables to go with this product

Additional components for laboratory technology

Find here the components that can be bought additionally for this product.

Compatible products